Libner : Your expert partner in industrial sheet metal work

Libner stands out as your trusted partner in industrial sheet metal work, offering a comprehensive range of services from laser cutting to mechanical welding, including metalworking on various materials such as steel, aluminum, and stainless steel.

Our highly skilled and experienced team works with dedication using a modern and efficient machine fleet, covering nearly 15,000 m² of covered space. Whatever your request, we are ready to take on the most complex challenges and deliver tailor-made solutions that meet your most specific needs.

WELDING

Backed by our expertise in the field of industrial bodywork, we offer welding assembly services for repair or modification projects of existing body structures. Our experienced team is ready to meet your needs.

BENDING

We offer custom sheet metal bending services, enabling the shaping of metal parts according to your exact specifications, to meet your design and manufacturing needs.

CUTTING

We offer custom sheet metal cutting services in a variety of materials, including aluminum, steel, and stainless steel, to meet your specific manufacturing and construction needs.

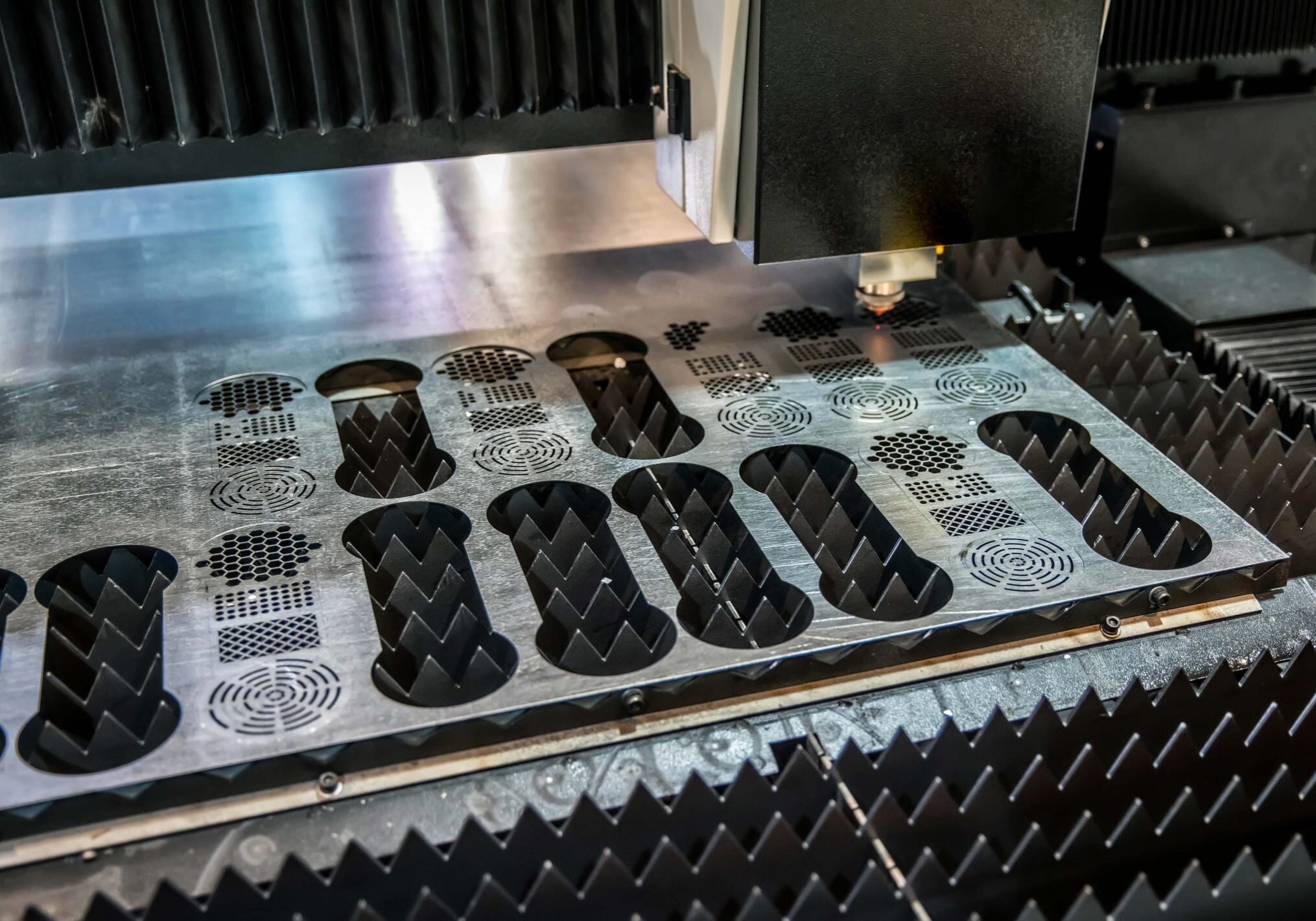

LIBNER also relies on cutting-edge production tools, such as the new TRUMPF TRULASER 3040 laser cutting machine – a “fiber laser” – which significantly increases production capacity, execution speed, and the quality of the finished product, while reducing material waste.

This 4000-watt machine is capable of cutting nearly all metals, including all types of steel and alloys, with a maximum thickness of 20 mm for steel and 30 mm for aluminum. The working area of our machine reaches up to 4 meters by 2 meters, allowing for the cutting of large-sized parts.

This innovative cutting technology allows us to efficiently adapt to all types of requests related to the production of our bodywork products. It also enables us to meet all subcontracting needs of our clients, whether for small or large production runs, while respecting their specific requirements in terms of lead times, quantities, and quality.

To automate the cutting process, the machine is connected to a loader-unloader system that transfers parts to and from an integrated storage unit. This allows raw or machined materials to be stored in designated bins, providing a practical and secure storage solution.